Introducing lignin as a binder material for the aqueous production

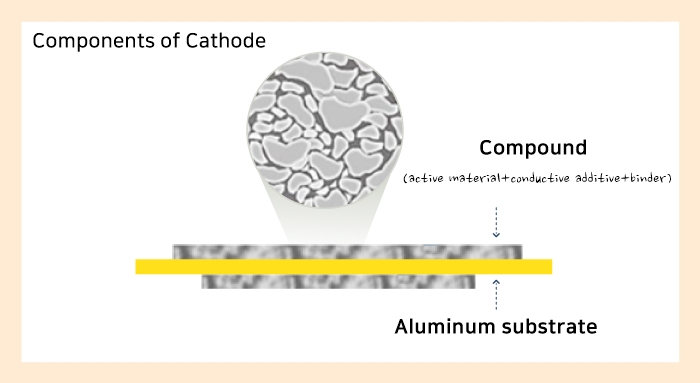

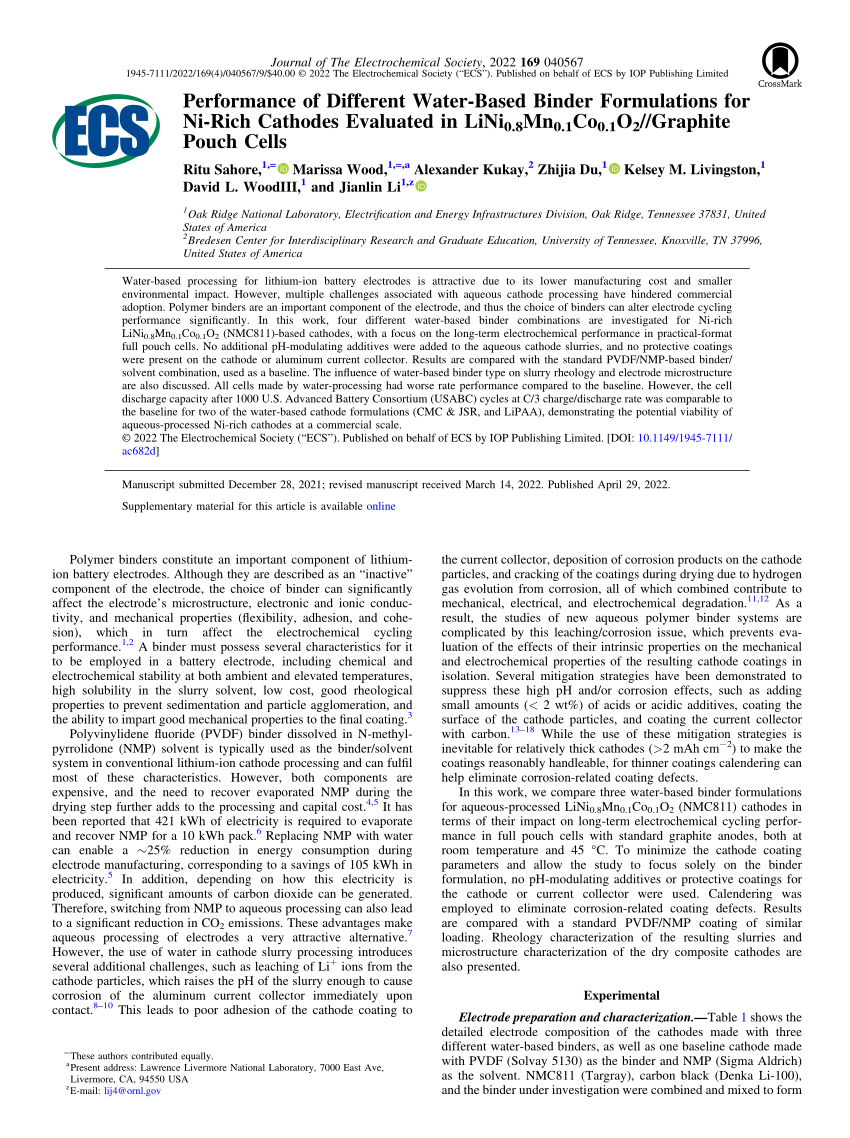

By enabling water-based cathode processing, the energy-intensive N-methyl-2-pyrrolidone (NMP) recovery step can be eliminated, reducing the cost and environmental impact of LIBs. Aqueous processing of high capacity Ni-containing LiNixMn1−x−yCoyO2 (NMC) cathodes is problematic due to lithium-ion(Li+) leaching

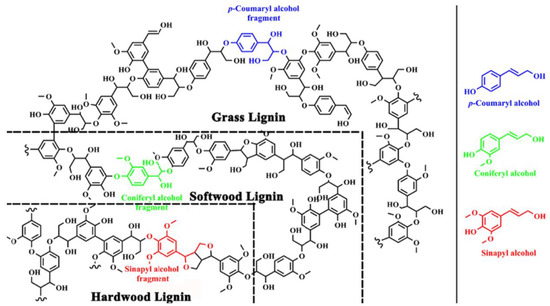

A review of the potential application of lignin in the production of bio- binder: challenges and opportunities

Batteries, Free Full-Text

tmax brand battery raw material for

Materials, Free Full-Text

Materials, Free Full-Text

Historical and prospective lithium-ion battery cost trajectories from a bottom-up production modeling perspective - ScienceDirect

Bringing Material Concepts into Conventional Biorefineries: Considerations of Sources, Preparations, and Applications of Lignin Nanomaterials

Materials Advances, Vol 4, Issue 2, 23 January 2023

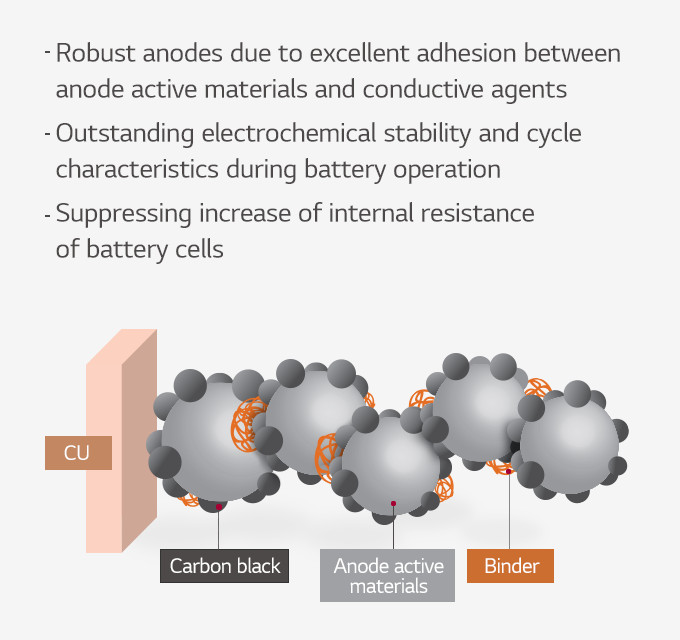

Performance of Different Water-Based Binder Formulations for Ni-Rich Cathodes Evaluated in LiNi0.8Mn0.1Co0.1O2//Graphite Pouch Cells

Cellulose molecular structure. Red: oxygen atoms; white: hydrogen

Polymers, Free Full-Text

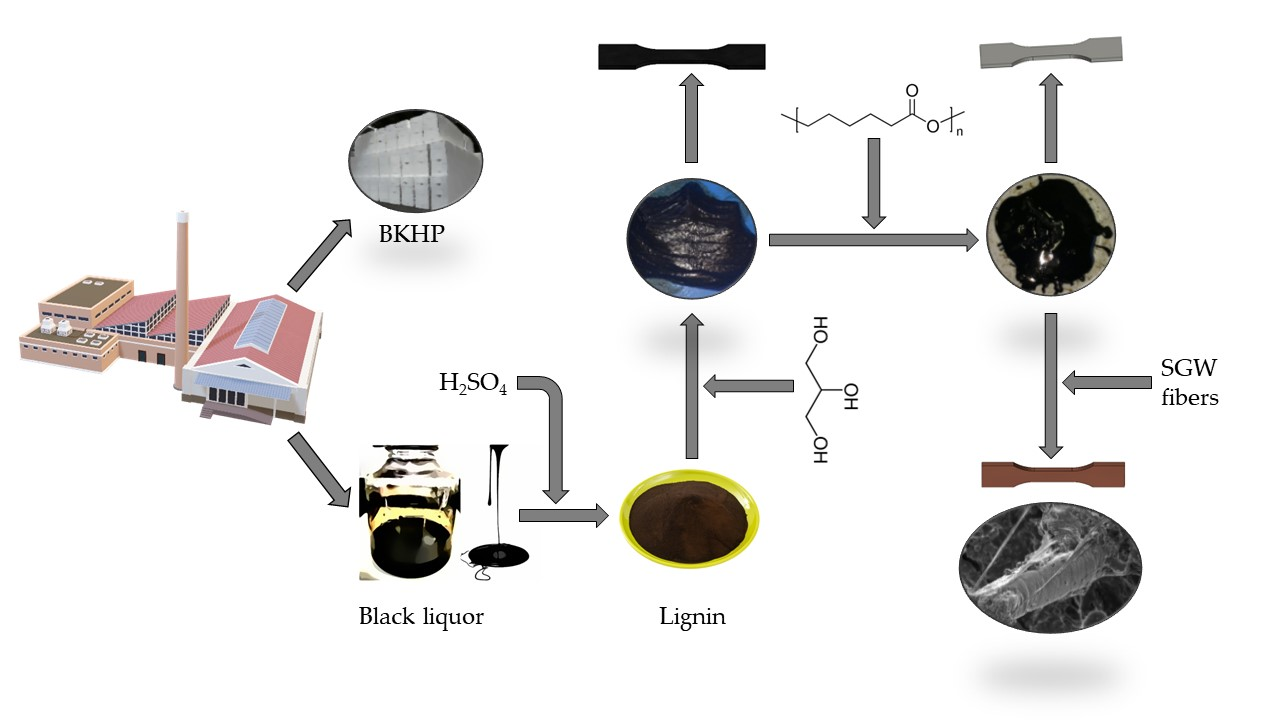

Introducing lignin as a binder material for the aqueous production of NMC111 cathodes for Li-ion batteries - Materials Advances (RSC Publishing) DOI:10.1039/D2MA00850E

Introducing lignin as a binder material for the aqueous production of NMC111 cathodes for Li-ion batteries - Materials Advances (RSC Publishing) DOI:10.1039/D2MA00850E

Simultaneous strengthening and toughening lignin/cellulose nanofibril composite films: Effects from flexible hydrogen bonds - ScienceDirect

NTNU Open: Introducing Lignin as a Binder Material for the Aqueous Production of NMC Cathodes for Li-ion Batteries