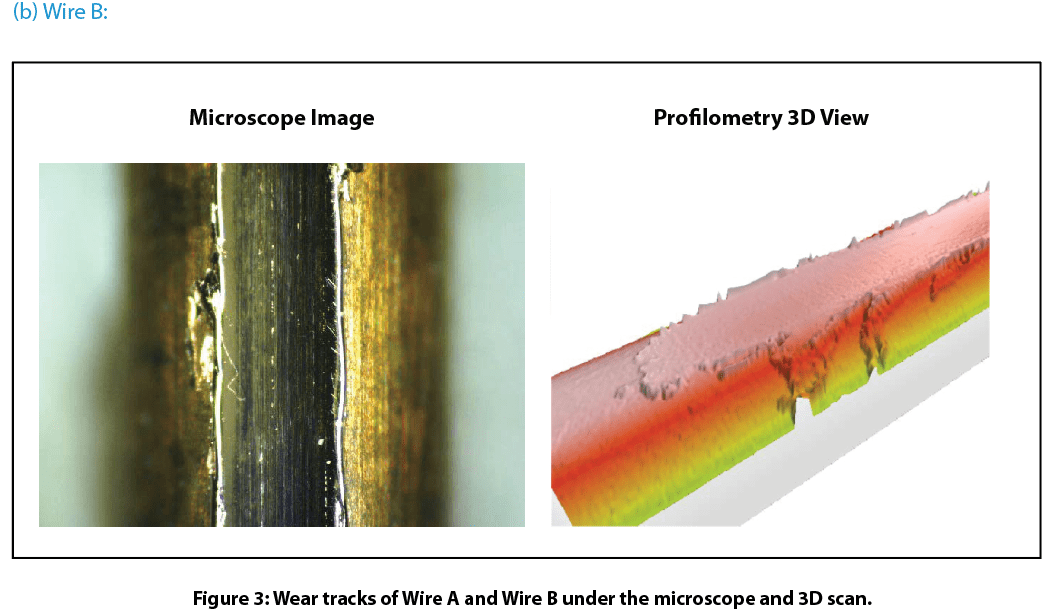

Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

We simulate a controlled wear process of different copper wire surface treatments. Scratch testing measures the load required to cause failure on the treated surface layer.

SEM morphology of adhesive wear surface of spool shoulder [3].

Anti-reflective, scratch-resistant coating for glasses and plastics - Innovation Hub@HK

Wear testing: (a) pin-on-disc machine and (b) sample with holder.

Ultimate Guide - Stainless Steel - Fabrication, Grinding, and Finishing with Abrasives - Empire Abrasives

Wilsonart 4 ft. x 8 ft. Laminate Sheet in Mangalore Mango with Standard Fine Velvet Texture Finish 7984383504896 - The Home Depot

【HAMMER】With bigger and heavier hammer head, the hammer is easier to hit. And the two ends of the hammer are detachable. We provide you 4

Punch Set Elite Tool Made of Solid Material Including Steel Punch and Hammer with Bench Block Ideal for Maintenance with Storage Case

What Do American Welding Society Wire Filler Metal Designations Mean? Red-D-Arc

Metals, Free Full-Text

Sensors, Free Full-Text

Flux Core Wire Types - Red-D-Arc Red-D-Arc

🔥 【Nail tech must haves set for nail art】: You will get 1*15ml Base Coat+ 1*15ml Top Coat. It is normal for a base coat and color gel to remain a

modelones Gel Top Coat, 15ml No Wipe Clear Glossy Gel Base and Top Coat Set, Soak Off Nail Lamp Acid Free Base Top Gel Nail Polish Starter Kit

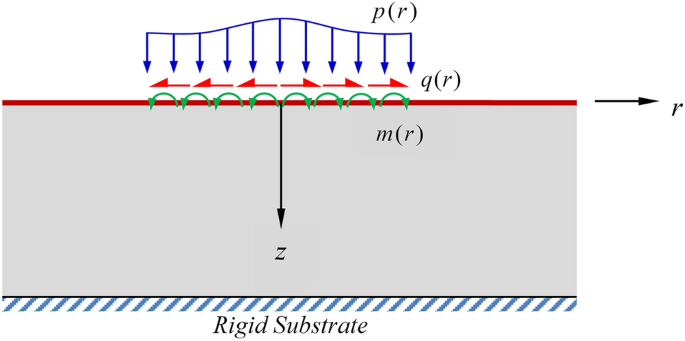

Elastic solution of surface loaded layer with couple and surface stress effects

They are solid brass, which means they are soft enough to cleaning or deburring with no scrach. Versatile kit & Commonly used for: Commonly used for

Brass Wire Wheel Brush Kit for Drill,Crimped Cup Brush with 1/4-Inch Shank,0.13mm True Brass Wire,Soft Enough to Cleaning or Deburring with Less